About Us

A Rich History

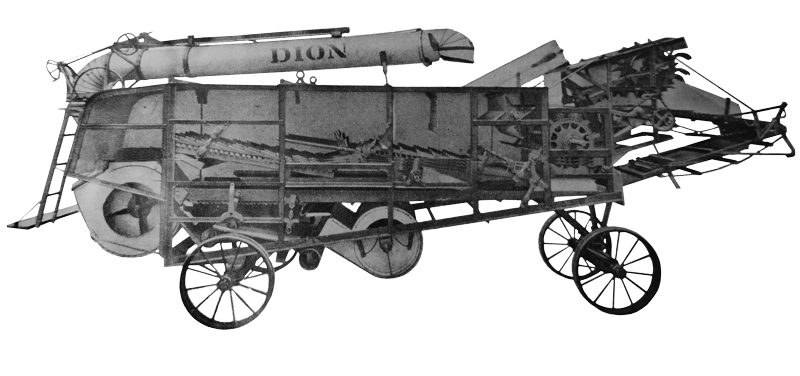

In 1920, brothers Amédée and Bruno Dion, dairy farmers and talented inventors, started the production of their first thresher. Dion & Frères was born.

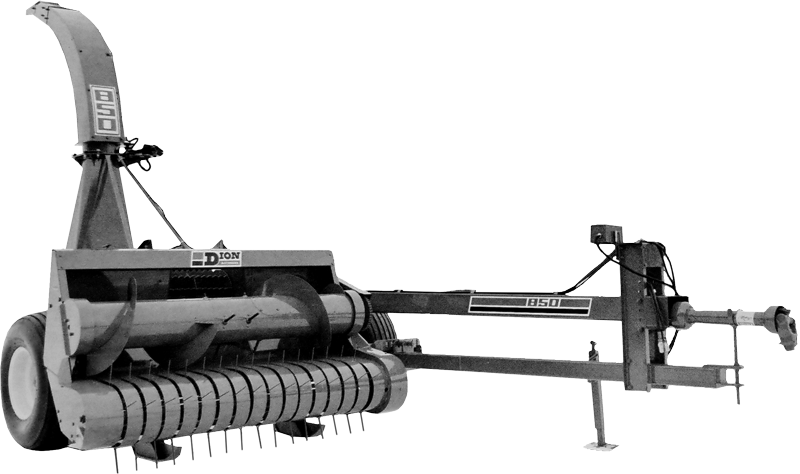

In the 1940s, their all-steel thresher made Dion the leader in the market. An on-site foundry provided all their cast parts. In the early 50s, the company diversified its product line with the fabrication of forage blowers and harvesters. A construction division, fabricating concrete slate silos & barn equipment, was also created.

In 1972, the company is sold to the Choinière family who focused on the silage equipment.

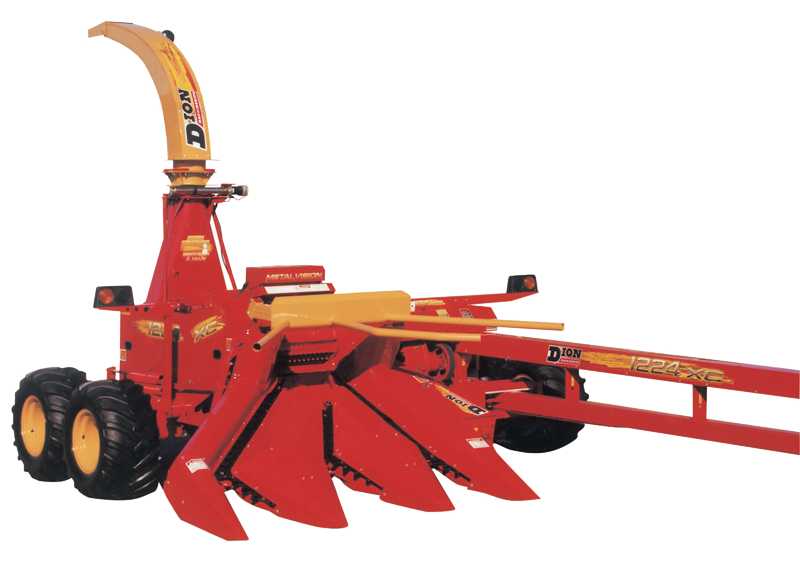

Located in Boisbriand, Quebec, Canada, at the same place where it was founded, Dion products are distributed in many countries across the world. From the first thresher in 1920, to the latest Scorpion 350 forage harvester with ISOBUS controls, Dion maintains the objective to continuously develop and improve its products making harvesting easier & more productive for farmers.

A new generation of shareholders for Dion-Ag

New owners of Dion-Ag

Philippe Nieuwenhof, Samuel Choinière, Marilyn Choinière, Mike Brown

This last spring, Dion-Ag owners made way for four new shareholders, already holding management positions within the company. The succession includes two members of the Choinière family, Marilyn and Samuel, as well as two other long-time employees, Philippe Nieuwenhof and Mike Brown; all of whom have been with the organization for over 10 years.

“This new milestone in the history of Dion-Ag is a mix renewal and continuity. We are building on 102 years of history, success, innovation and challenges that have shaped the resilient character of the organization, to carry out our plans for the future.”

– Philippe, nouveau Président.

Georges Choinière, former CEO of the company, will now hold the position of general manager. His main mission will be to ensure the implementation of Dion-Ag’s new strategic plan.

To accomplish this goal, the silage equipment manufacturer relies, among other things, on major investments in technology that will enable it to increase its productivity. Difficulties in the supply chain combined with the labor shortage that manufacturers have been facing in recent years, have demonstrated the need to review and optimize manufacturing processes in order to achieve the set objectives. The acquisition of new, more efficient management software and of a first welding robot are some of the tools put in place to succeed.

In addition, an ambitious new product development plan has been implemented to sustain significant growth expected over the coming years.

All great news for a constantly evolving company!

Provider of useful and profitable technology, attentive to customer’s needs.

Our company focuses on innovation to meet the ever-evolving needs of today’s farmers. Designing unique, innovative, reliable & profitable products is our main mission.

A Dynamic Team

Dion-Ag Inc. relies on dynamic & devoted people with varied experience & expertise with a common goal of producing high quality products.

Devoted to R&D

(research and development)

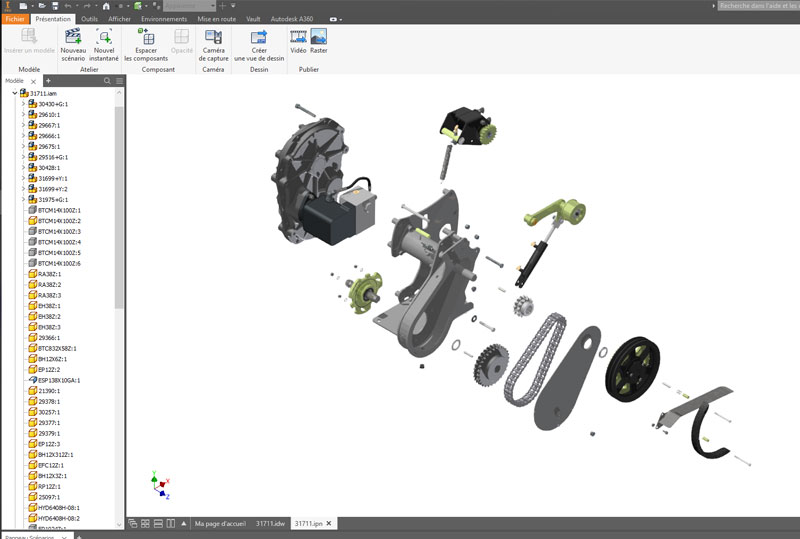

It is a scientific approach, focused on efficiency, that guides our engineers in the development of our products. Each project starts with a thorough concept development, rigorous data acquisition & comparative analysis to yield an innovative design with the best quality/price ratio.

The 3D design and simulation, with the latest software, allows for design optimization even before the first prototypes are ever built. The farming experience of our personnel ensures that the products developed are adapted to the reality of our customers and that the technology developed, brings useful benefits.

Expert partners, in various fields of competency, support our team to obtain final product quality at every level.

Farm Tested

Each prototype is put through a testing protocol consisting of stationary and real-life field tests. Our experienced technicians, provide feedback right from the fabrication of the first prototype, to evaluate the design and the ease of maintenance. Our engineers participate directly in the field tests with the help of a community of farming test pilots. The machines are put in real conditions under variable intensity on many farms. This provides feedback early in the developmental process to quickly improve the design.

Latest Fabrication Methods

The possibilities offered by recent fabrication methods are integrated at the design stage. For example, the flexibility and precision that 3D laser tube cutting allows is exploited in some parts to improve assembly methods, reduce tooling and consequently the cost of the machines. High quality suppliers ensure the fabrication of parts comply with our specifications and needs.

The Dion-Ag factory in Boisbriand contains dedicated welding and assembly departments operated by qualified welders and assemblers. Each of our machines are painted with a superior quality powder coat paint on a prepared sandblasted surface resulting in the best possible adhesion and durability.

Continuously Improving Quality

Each machine undergoes an exhaustive inspection process which is continuously being tweaked and improved upon.

Dynamic testing and verification ensure all machines are delivered correctly adjusted and ready to operate. We value the relationship we share with our customers and are always listening for comments and feedback.

For new products, or even those that have been on the market for years, any new useful information is analyzed and may then applied quickly into production.