Products

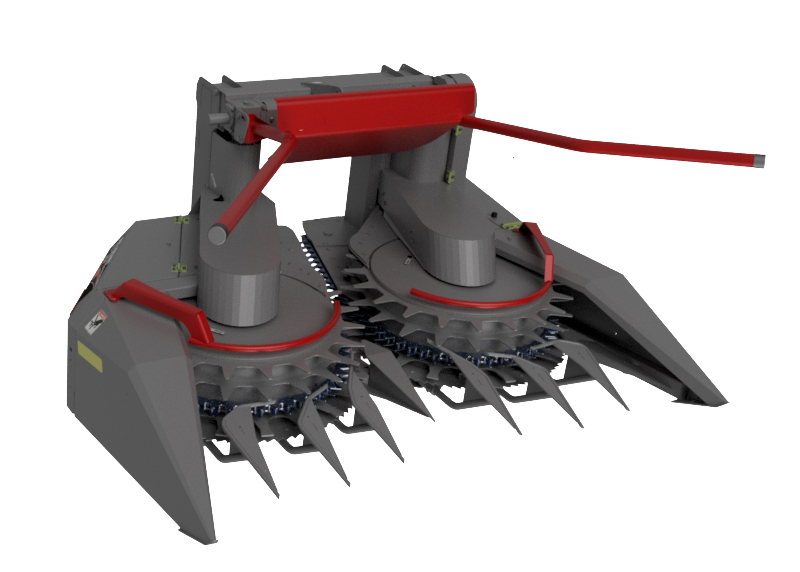

Ideal Cut

The rotary blades are driven by v-belts and turn the opposite direction of the drums. This design eliminates vibrations. The four blade sections, per disk, are made or harden spring steel with tungsten carbide tips offering self-sharpening effect, making them exceptionally durable. Replacing a section is done in just a few minutes at an affordable cost. Through the impact cut, the stalks are also shattered to facilitate their decomposition and reduce tire damage.

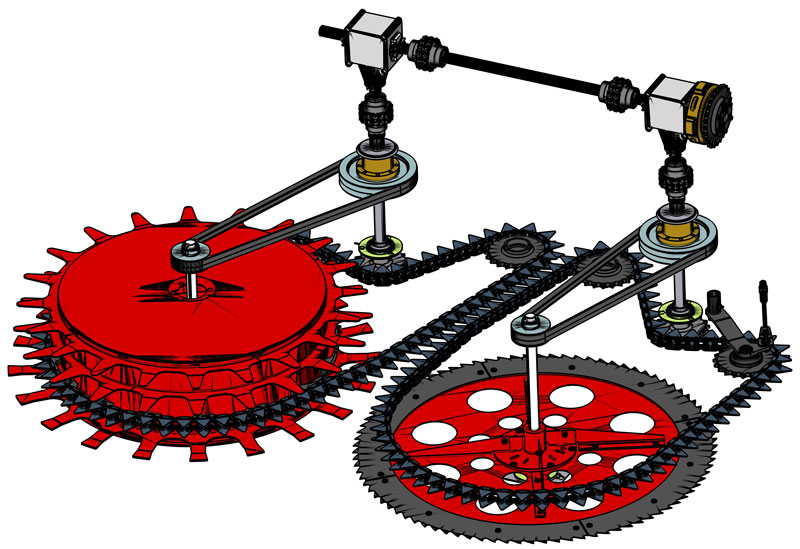

Unmatched Simplicity

The F64 head is surprisingly simple. The drive system contains few parts and requires low power to operate. Only two chains drive the two gathering drums to transport the crop to the harvester. The Dion exclusive O-ring chain design requires low maintenance. The use of sealed bearings reduces daily greasing. The overloads and starting loads are absorbed by a friction clutch to operate smoothly and eliminate the need for shearbolts.

Higher Silage Quality

By maintaining the crop in the gathering chains, with continuous flow to the harvester feedrolls, without using a transverse auger, the stalks are fed base first and aligned perpendicular to the feedrolls. This provides a uniform length of cut without unwanted long particles that affect storage compaction and silage fermentation quality.

Boost your harvester performance!

A uniform flow, full width harvest unaffected by row alignment, increases your harvester performance. It provides more throughput per hp, less driver fatigue and more acres per day, all increasing productivity and profitability.

Dion rotary heads feature a universal frame and offer drive kits adapted to most pull-type harvesters on the market. See the option tab for more details.

The F64 header features a universal frame.

Adapter kits are available to hook up the header on most pull-type harvester on the market. For tighter budgets, get the most return on your investment with the rotary corn head on your current harvester today. At the purchase of your next Dion harvester, only the drive kit will be necessary to replace. No matter the situation, you obtain the best resale value with the modular adaptors.

Compatible Harvesters:

- Dion Scorpion 300/350, 2430

- Dion F41, 1224

- John Deere® 3950/55/70/75

- NewHolland® 900, FP230/240

- Gehl 1065/75/85 1265/75/85

- NewIdea® 1500 – Hesston® 7500

Rotary Lift Kit

For difficult down corn conditions, a rotary stalk lifter is available. It can rotate in both directions, with variable speed, while being driven directly from the tractor SCV.