Products

B58 Silage Boxes

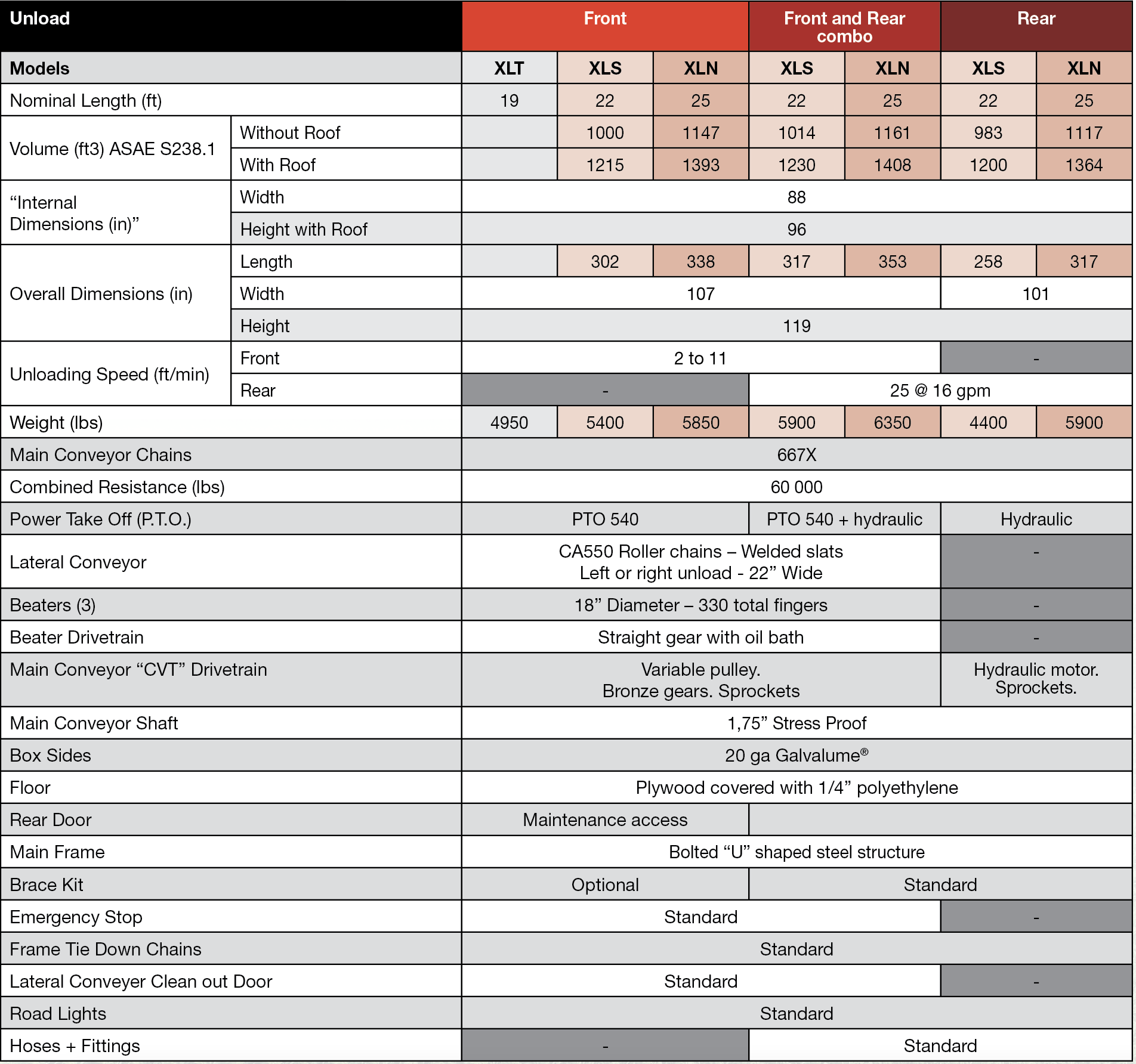

Reliable & versatile, they have proven their worth and left their mark.

Dion silage boxes need no introduction. Recognized and proven, they remain the farmer's favorites for any farm size.

Noted for their uniquely design beaters, they benefit from a Continuously Variable Transmission (CVT) that allows for that precise unloading speed adjustment.

Across the range of available sizes, they have the advantage of being able to adapt to any loading and unloading conditions, thanks to an easy-to-use hydro-mechanical design and a remarkable efficiency. Versatile and configurable with a multitude of options, allowing them to meet the various needs of silage transportation.

The B58 boxes have impressive standard features, guaranteeing quality and durability.

Rigid and Durable Construction

The frame is made of heavy duty steel coupled with transverse reinforcement rods ensuring long-term durability. All Dion products are protected by a high quality powder coating and a sandblast preparation that ensures excellent adhesion. The side sheets, made of Galvalume®, offers a high corrosion resistance.

Polymer Floor

The low-friction polymer that covers the floor ensures clean unloading and long life.

Robust Conveyor Chain

The main conveyor features 4 heavy duty 667X or 667H chains, depending on the model, that offers a combined resistance of 60,000 or 40,000lb respectively. The welded slats prevent long term damage.

Easy Maintenance

The lubrication points are grouped and at a reachable height. Verification of oil levels and chain lubrication are quick and easy thanks to direct access.

Front Unload Models

Uniquely Design Beaters

The elliptical beaters sweep the load continuously which allows for very uniform & fast unloading without an overloading danger. The roller chain side conveyor quickly transports the silage to the blower for a large capacity.

“CVT” Driven

The silage box drive is engaged by a resistant triple belt which smoothly starts the side conveyor. The main conveyor is driven by a set of variable pulleys that allows the forward speed to be adjusted from 2 to 11ft/min. A hydraulic drive option is available (See options section).

Rear Unload Models

B58 boxes are also available in dedicated rear unload versions.

Driven by a hydraulic motor, unloading is fast. At speeds up to 17ft/min, it takes 1m30s to unload even the largest models. The rear door unlocks automatically when the conveyor engages and locks passively when stopped. A door delay closing system is optional.

Combo

The front and rear unload silage box is ideal for all farms and custom contractors. With either tower or pit silos, the B58 Combo integrates front and rear unloading capabilities. The conversion between unloading sides is done in less than 2 min.

Front Unload Hydraulic Control

The front unload mechanism can be hydraulically driven as an option. The conversion can be done at any time.

Beaters and main conveyor engagement through hydraulics is also available, allowing full operation from the tractor/truck cab. If you opt for a side conveyor extension, a hydraulic cylinder opening system is optional.

Side extension

Installed on one or both sides, they increase the box capacity for models without roof. Expanded steel offers good visibility when loading.

Roof

Dion's corrugated steel roofs offer the greatest rigidity and simplicity. Made out of 20ga Galvalume® sheets, they reinforce the frame and resist the corrosion caused by silage.

18" (45cm) Foldable Conveyor Extension

To facilitate unloading at the blower, the extension provides additional clearance. A retaining spring facilitates folding. Hydraulic folding is optional.

Kit for Top Loading

Standard on some models, the reinforcement kits consist in adding extra posts on each side and a top brace.

Truck Mounting Kit

The kit includes all parts for a regulatory installation on a truck.